In terms of the questions we get regarding RoastLog, the one we get most often isn’t even about RoastLog, per se. The one area of complication for our system, and any temperature measuring system, is how exactly to accurately and precisely measure what you’re interested in. In our case, that’s your coffee.

There are many different ways to measure temperature: an old mercury thermometer from when you were a kid, infrared devices, RTD, etc. Once which had been around for a very long time and is well understood is the thermocouple. I’m going to attempt to give a crash course in thermocouples as they apply to coffee roasters.

How thermocouples measure temperature

Thermocouples (or, TCs) have many advantages: inexpensive, reliable, easily understood, flexible, etc. Arguably the biggest advantage is that they’re simple…really really simple. A thermocouple is no more than two wires made of different metals welded together at the end. That’s it. Now, the important thing to know here is that the principle behind TCs is completely different from that of the old mercury thermometers you’re used to, or any other temperature sensing device (AFAIK). TCs do not touch an object then spit out a temperature at the other end. Instead, TCs produce a very small voltage which changes based on the temperature where the two wires are welded together. The relationship between temperature and voltage are known, so by measuring the voltage of the TC we can calculate the temperature.

That Fluke hand-held meter you have….that thing measures the voltage from the thermocouple, does some math, and then spits out a temperature for you. Our Data Bridge does the exact same thing. I’m glossing over a couple of details, but that’s the general principle.

Thermocouples “types”

The questions which pops up over and over is: “What type of TC do I need”. First off, there are different “types” of thermocouples which designate what type of material the wires are made out of. We don’t really care what the materials are, but we do care that there are different types since we need our entire system to match. The two most popular are “Type J” and “Type K”.

If you’re using a digital display which takes Type-J, you need to make sure that the TC wire and all of it’s connectors are Type-J. The RoastLog Data Bridge works with Type-K (we’re currently working on getting it to work with either Type-J or Type-K). We’ve found that the vast majority of roasters who have TCs are running Type-J. Does that mean you can’t use RoastLog? Not at all. We continue…

Thermocouples variants

After the type of thermocouple has been decided, the next thing to think about is the physical style. What we do here is highly customizable since there are TC manufacturers out there who will make almost anything you need. Since a TC is just two wires which connect at one point (the end), we should put those wires inside something protective before we install it into our roaster. For roasters, you’ll end up getting a TC with a stainless steel probe/sheath. Inside this probe will be the TC wires.

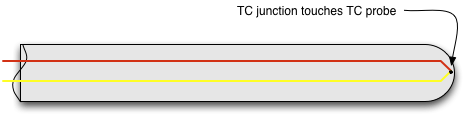

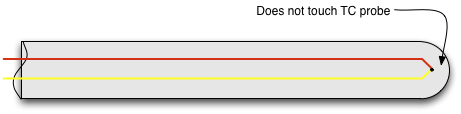

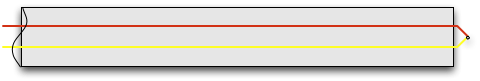

This may sound a bit complex, but it’s fairly simple. The first option we face is the junction type. Below are drawings of the three types, grounded, ungrounded and exposed tip, along with some more explanation. In all of these drawings, the red and yellow represent the two different TC wires. At the end, the black dot shows where they’ve been welded together. You never see this when you buy these things…you’ll just see a stainless steel probe with some wires coming out the end (the left side, in our drawings).

Grounded thermocouple

With the grounded thermocouple, the TC junction physically touches the inside of the stainless steel probe. This is great, since temperature changes can be sensed very quickly. However, remember back when I said that what’s actually measured is the voltage? Well, imagine if the probe itself starts picking up some voltage like an antenna. Now the TC wire picks that up itself and the measure device sees a higher voltage, which results in a higher temperature reading. This can, and does, happen in coffee roasters. For this reason, we don’t recommend grounded TCs.

Ungrounded thermocouple

In the ungrounded version, the TC junction sits in free space and does not come in physical contact with the SS probe. This is good since any voltage picked up by the sheath will not be transmitted to the TC itself. We recommend this version since the TC is protected and electrical noise will not affect your readings. The downside to this is that response times are a bit slower.

Exposed tip thermocouple

The final variant is the exposed tip. Here, we get the best of both worlds. The TC junction doesn’t touch the sheath, so it’s electrically isolated. Also, the tip is in direct contact with your beans and the drum air. The downside to this one is that the tip can get beat up, and wears out much quicker than the other two versions. I’d actually like to runs some tests with exposed tips and see how long they last and what types of reading we get from them.

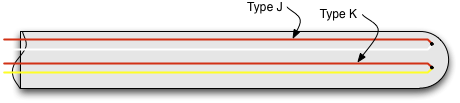

Dual-probe thermocouples

Phew, that a lot, but we’re not done. Many roasters nowadays come with TCs already installed. Or, people are logging with some other system they’ve rigged themselves like a hand-held Fluke meter or a small Watlow controller/reader. It would be great if folks could “split” they’re existing TC so that it would go to their existing reader as well as the RoastLog Data Bridge. Unfortunately that’s impossible, based on one of the principles I glossed over for TCs. Since you can’t just splice the wires like you would with some speaker cables, what do you do?

Instead of getting a probe with one pair of wires inside, you get a probe with two pairs. This is called a “dual-probe” TC.

Dual probe thermocouple. Red/white is the Type-J, while red/yellow is Type-K.

Here, the neat thing is that we can mix and match types. What we order for our customers are dual-probe Type-J and Type-K. The Type-J typically goes to existing devices, and the Type-K goes to the Data Bridge.

That’s it for now. We didn’t even get into the probe sizes, lead lines, connector types, etc. But, that stuff is easy to customize so we can save it for another time. This post was meant to cover just some highlights on thermocouples so roasters have a bit better idea of where those numbers are coming from, and also hopefully help out when considering adding RoastLog to your roasting operation.

There are many good online resources out there on TCs if you’d like to learn more detail. Omega, Wikipedia and this guy contain some good content.

3 Comments

Robert Bedwell · November 9, 2010 at 3:32 am

I am extremely interested in your software for logging my roasts. I am trying to determine if my Thermocouple is compatible. It does not have a built in data logging function. It is a Fluke Model 52II and accommodate two probes.

Joshua · February 21, 2011 at 6:38 pm

I would love some more information on your product, in particular in relation to the TC

thank you

Our 2010 blog in review « RoastLog Blog · January 3, 2011 at 6:33 pm

[…] Thermocouples, and beyond! June 2010 1 comment 4 […]

Comments are closed.