I just returned from the big island of Hawaii where a few things happened. First, and most importantly, Kristi and I got married. Neither of us are into the big wedding thing, so it was just the two of us, Pinkie the wedding coordinator from the hotel, and our local officiant, Dard Aller.

Dard performed a beautiful traditional Hawaiian ceremony for us. Everything was perfect…we really couldn’t have asked for anything more. At then end of the ceremony, we did some official paperwork signing and during the course of some small talk, learned that Dard is not only a wedding officiant, but also a Kona Coffee producer! (check him out at: http://www.dardroast.com)

We had plans to head to Ka’u to visit another farm on Sunday, but a marathon day in the car to see the volcanoes on Saturday put the squash on that plan (since Ka’u was about 2 hrs. one-way). A few Twitter direct-messages later (@mykonacoffee) and we had plans to see Dard’s operation. His place was super close to a snorkeling spot we were planning on visiting anyway, so it was perfect.

This was pretty cool for me since I had never seen any type of production before the beans arrive in their bags. Dard’s place is a pretty small operation, with about 100 trees. It’s not really a “farm” per-se, since the coffee trees grow all over his properly amongst the banana, mango, avocado and other types of trees, but the steps involved in production of the coffee appear to be pretty much the same as a bigger farm, albeit on a much small-scale.

First off, we picked a few beans. Lucky for me this time of year has the trees producing ripe cherries, so it was easy to just walk up and get a couple handfuls into the basket. Another tidbit, Dard doesn’t use any sort of pesticides. While not organic “certified”, the coffee is grown organically. Dard says he can pick about 100 lbs/day. Not bad! He’s also done about six Ironman triathlons, so it’s not too surprising.

After the picking, the next step is pulping the beans, where the bean is extracted from the cherry. We squeezed out a couple of beans to see what they look and feel like straight from the cherry. I was surprised at how thick and slimy the mucilage was. I had seen beans with the parchment still on them (dried mucilage), but never had the experience of pulping a coffee bean either by hand or mechanics. The small bit of beans that I had picked got its turn through Dard’s small pulper. Previous to getting this thing, he and his wife used to pulp the beans by hand while watching TV!

After pulping, the slimy beans go in water where the floaters (undeveloped beans) are removed and the remaining beans sit overnight. This is the fermentation stage where the mucilage breaks down a bit. After about a day, the beans go out onto the drying trays where they soak up the warm Kona sun. With these trays, Dard says that it takes roughly 10 days before the beans have reached the proper moisture content. From here, the beans are still encased in thin “parchment” which is the dried mucilage. It’s the huller’s job to extract the parchment from the bean..the huller is a pretty simple device and made quick work of few pounds of beans which Dard had already dried.

Finally came the part where I actually know a little something…roasting. Just like all of the other equipment, I had never seen this type of roaster. The thing is simple, but it gets the job done. It reminds me of a single barrel sample roaster which has grown up. The barrel fits about 10 lbs of beans and there’s a big burn beneath it. We did a 7lb batch while brewing up some coffee which Dard had roasted earlier in the day.

It was really neat to see all of this since Dard has really been learning as he goes and getting tips from other producers in the Kona area. Not only that, he was really interested in learning more about the whole process and we talked quite a bit about roasting and brewing techniques. This is one part of coffee which I love; many people become excited about coffee and the entire process and are eager to learn more and improve their skill set. I was also completely impressed that one guy could do all of this practically on his own….all the way from harvesting to delivering roasted coffee to consumers and stores in town. Even my bride Kristi had a great time…mostly due to Dard’s good energy and enthusiasm (although, she is going to be *really* interested when the cacao trees mature and we start seeing some Dard Chocolate).

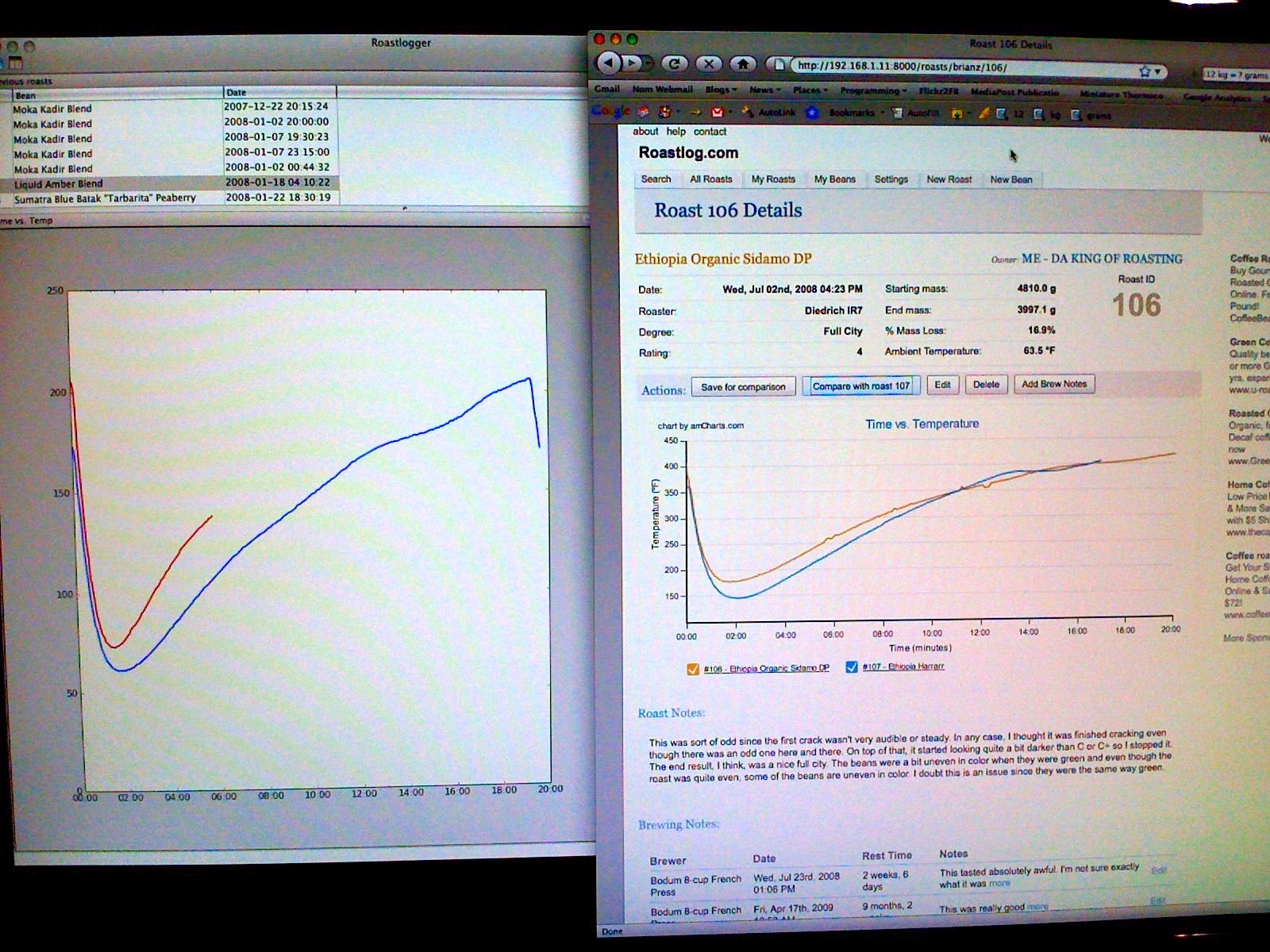

At the end of our tour I got what I’ll call a DardLog…not quite RoastLog, but it serves the same purpose. Dard, thanks again for a very special wedding ceremony and a great tour!

4 Comments

Silas Toms · October 12, 2010 at 8:48 am

Yeah Brian! Congrats all around, to both of you.

Dard Roster · October 15, 2010 at 9:52 pm

Brian —

My new mentor, mahalo for all your wisdom.

What fun. Touring the trees, pulping and hulling.

When it came to the roasting roastlog.com RULES!

Derek Murphy · October 8, 2012 at 11:44 am

Hi – I really like the picture at the top, did you have a photographer? If so who?

brianz · October 8, 2012 at 9:32 pm

@Derek – Not really…our “photographer” was a random person who was sitting near our wedding spot when we showed up. We handed her a camera and said, “Just point and shoot”….she did a great job!

Comments are closed.